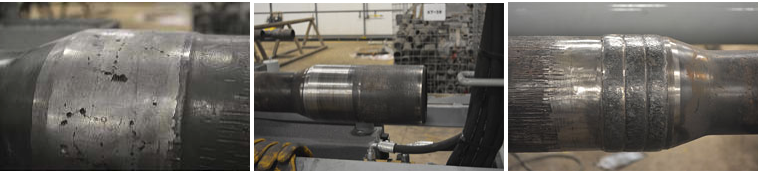

We also offer hardbanding repairs including the grinding and removal of worn hardbanding and replacement with new materials.

We also offer hardbanding repairs including the grinding and removal of worn hardbanding and replacement with new materials.

Using our high speed grinding unit, we have the ability to remove old, damaged, or unacceptable hardbanding material, preparing the surface for re-application of the desired hardband material.

During the removal process of defective hardbanding, it is often necessary to remove a portion of the underlying base metal.

Our grinding process allows us to remove not only the defective hardbanding, but also the base metal, which sometimes contains contaminates that affect the quality of the hardbanding material after the reapplication process.

Unlike traditional “plasma” type removal processes, Lead NDT’s process ensures that the surface being repaired stays well below temperatures (never exceeding 150 degrees) that may compromise the integrity of the parent metal.